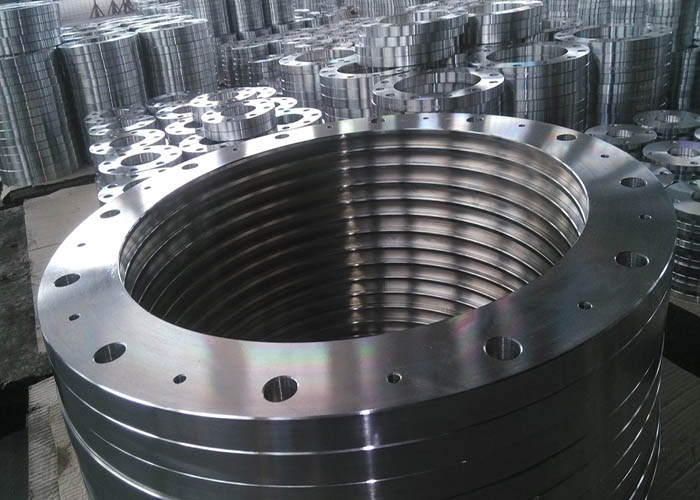

Flens van gelegeerd staal

Specificatie:

| Rang | ASTM / ASMEA182F1 / F51 F9 / F111 F221 F91 |

| Standaard | ANSI-flenzen, ASME-flenzen, API, MSSP, BS-flenzen, DIN-flenzen, EN-flenzen, NACE enz |

| Grootte | 1/2 "tot 36" |

| Type | Lasnekflenzen (WNRF), opsteekflenzen (SORF), blinde flenzen (BLRF), overlappende verbindingsflenzen (SOLJ), lassen |

| Flenzen (SWRF), geschroefde (schroefdraad) flenzen, lange lasflenzen (LWNRF), blinde flenzen voor bril | |

| Afstandsstuk en blinde flenzen, ringvormige verbindingsflenzen (RTJ), verkleinende flenzen, verhoogde flenzen (RF), flenzen met opening | |

| Flenzen met grote diameter, aangepaste flenzen, tekeningflenzen, gesmede flenzen, plaatflenzen, plat vlak Flenzen, enz | |

| Dimensies | ANSI / ASME B16.5, B 1647 Serie A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ENZ. |

| Klasse / druk | 150#, 300#, 600#, 900#, 1500#, 2500# |

| PN6, PN10, PN16, PN25, PN40, PN64 ENZ |

ASME SA 182 AS Pipe Flange Equivalent Material

| Material Group | Common Name | Type | UNS | Forging Spec. | Casting Spec. Equivalent | DIN | DIN W. No | Toepassing |

|---|---|---|---|---|---|---|---|---|

| Low AS | Moly Steel | C-1/2Mo | K12822 | A182-F1 cl2 | A217-WC1 | 15M03 | 1.5415 | Up to 470ºC* (875ºF) |

| AS Chrome Moly | 1.1/4Cr-1/2Mo | K11572 | A182-F11 cl2 | A217-WC6 | 13CRM044 | 1.7335 | Up to 593ºC (1100ºF) | |

| 2.1/4Cr-1Mo | K21590 | A182-F22 cl3 | A217-WC9 | 10CRM0910 | 1.7380 | Up to 593ºC (1100ºF), HP steam | ||

| 5Cr-1/2Mo | K41545 | A182-F5/F5a | A217-C5 | 12CRMO195 | 1.7362 | High temp refinery service | ||

| 9Cr-1Mo | K90941 | A182-F9 | A217-C12 | X 12 CrMo 9 1 | 1.7386 | High temp erosive refinery service | ||

| 9Cr-1Mo-V | A182-F91 | A217-C12A | X 10 CrMoVNb 9 1 | 1.4903 | High pressure steam |

Chemical Element of Alloy Steel Flange Material

| Rang | C | Mn | Si | P. | S | Cr | Ma |

|---|---|---|---|---|---|---|---|

| F1 | 0,15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F5 | 0,15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F9 | 0,15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

| F11 | 0.5-0.15 | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 1.0-1.5 | 0.44-0.65 |

| F12 | 0,15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F22 | 0.50.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F91 | 0,15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

Mechanical Properties of ANSI B16.5 Alloy Steel Slip On Flange

| Rang | Treksterkte | Opbrengststerkte (0,2% offset) | Verlenging |

|---|---|---|---|

| F1 | 275 | 485 | 20 % |

| F5 | 275 | 485 | 20 % |

| F9 | 380 | 585 | 20 % |

| F11 | 205 | 415 | 20 % |

| F12 | 275 | 485 | 20 % |

| F22 | 205 | 415 | 20 % |

| F91 | 380 | 585 | 20 % |

Specification Chart of Alloy Steel Weld Neck Flange

| ASTM-specificatie | ASTM A182 , ASME SA182 |

|---|---|

| Size in inch | 1/2 inch (15 NB) to 48 inch (1200NB) |

| Standaarden | ANSI/ASME B16.5, B16.48, B 16.47 Series A & B, EN-1092, BS4504, BS 10, DIN |

| Class and Pressure Chart | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

ASME SA182 AS Orifice Flenzen,

ANSI B16.5 legering plaatflenzen,

Gelegeerd staal A182 buisflens,

Legering A182 Lap Joint Flenzen,

Blinde flens van gelegeerd staal

Flenzen van gelegeerd staal

Chromen Moly plaatflens

A182 gelegeerd stalen lasnekflens,

Flens met schroefdraad van gelegeerd staal